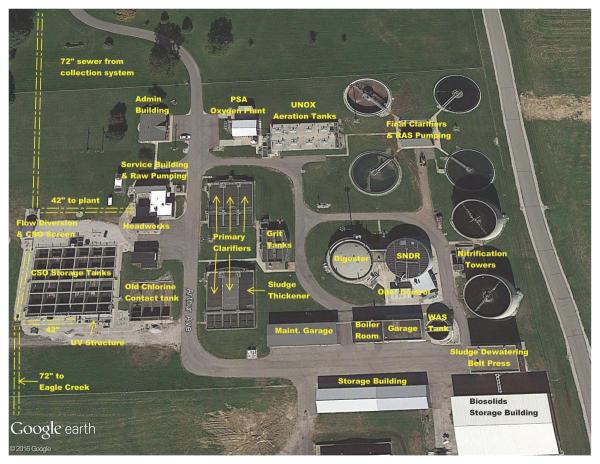

About the Plant

Speedway Wastewater Treatment Plant is a Class IV treatment facility:

- Design flow of 7.5 million gallons per day (MGD)

- Primary treatment capacity of 11.25 MGD

- Peak secondary treatment capacity of 8.9 MGD

The treatment process consists of the following:

- Influent fine screen, grit collectors, primary clarifiers, oxygen activated sludge, secondary clarifiers, nitrification towers, and ultraviolet disinfection

Solids handling consists of the following:

anaerobic digestion, storage nitrification denitrification reactor (SNDR), and belt filter presses for de-watering

Speedway sewer system is approximately 95% sanitaryand 5% combined.

- Inflow and infiltration is a problem and adds a significant amount of clear water to the sewer system. Because of this, a combined sewer overflow (CSO) is located at the headworks to the treatment plant. Whenever the flow exceeds the hydraulic capacity of the main sewer, a portion of the wastewater stream is diverted to the CSO storage tanks. When the level in the sewer drops to a normal level the wastewater in the storage tanks is pumped into the plant for full treatment.

Step-by-Step Treatment Process:

The treatment process begins when the flow passes through the influent fine screen. This screen removes the large material such as cans, bottles, etc. from the waste stream.

The flow volume is then measured by means of a 36-inch parshall flume and ultrasonic flow meter. A pH meter is installed at the flume to continuously monitor the pH. The wastewater enters a wet well where it is pumped to the grit tanks.

In the grit tanks, the flow velocity is slowed down so the heavier grit material such as sand, rocks, etc. can settle out. The settled grit is then pumped to a grit separator that separates the water from the grit material. The water flows back to the head of the plant to be treated and the grit is collected in a dumpster and disposed of in a landfill.

After grit removal, the wastewater flows to the primary settling tanks. In these tanks the flow velocity is slowed further, causing the lighter material to float to the top and the heavier material to settle to the bottom. The floating material (scum) is collected and sent back to the head of the plant to be removed by the influent fine screen. The heavier material (sludge) is collected and pumped to a thickening tank and then to the anaerobic digester for further treatment.

Now that primary treatment has been accomplished, the primary effluent flows to the oxygen activated sludge process (Unox). In this process, the most important treatment takes place. Microorganisms (bugs) are utilized to absorb and break down the waste materials in the wastewater. This is accomplished by providing the bugs with food (organics in the wastewater) and oxygen, which is generated onsite by the Pressure Swing Adsorption unit (PSA). The PSA unit takes atmospheric air and separates the oxygen from the nitrogen. The nitrogen is vented to the atmosphere and the oxygen is sent to the Unox tank to be used by the bugs. Mixers in the Unox tank keep the contents suspended to better convey the waste material and oxygen to the bugs. As the bugs multiply, they become over populated and some of the bugs must be removed from the system (wasted) daily in order to maintain a controlled environment. This wasted material flows back to the head of the plant and then settles out in the primary clarifiers.

After treatment in the Unox tank, the flow goes to the final settling tanks. Here the bugs settle to the bottom leaving a clear liquid at the top. The clarified effluent continues downstream for further treatment. The settled bugs are returned to the Unox tank or removed from the system.

The wastewater is now ready for ammonia removal in the nitrification towers. In the towers, a fixed plastic media is used to grow special ammonia-removing bacteria. The wastewater is pumped to the top of the towers where it is distributed across the surface of the media. As the water trickles down through the media, the bacteria convert the ammonia to nitrates.

The wastewater now flows to the ultraviolet process where UV light kills the pathogenic (disease-causing) bacteria. The fully treated wastewater is then discharged to Eagle Creek.

The solids (sludge) that have been removed from the wastewater during treatment must now be processed. Solids handling is accomplished in three phases. First, the sludge is treated in the anaerobic digester by heating it up to about 95 degrees and holding it for at least 15 days. During this process pathogen reduction takes place as the sludge is converted primarily to methane, carbon dioxide, and cellular material, thus rendering the sludge relatively stable. The sludge receives further treatment in the SNDR process to reduce the ammonia content. The digested sludge (bio-solids) is then de-watered with a belt filter press and pumped to a storage building. The bio-solids are utilized on farm land as a fertilizer and soil conditioner.